10 Innovative Features of the Weil-McLain 94 Series Boiler

The Weil-McLain 94 Series cast iron, heavy-duty boiler is uniquely engineered to provide efficient heat for churches, apartments, offices, schools, as well as other institutional and commercial buildings. The Weil-McLain 94 is offered for steam or water in a total of 18 different sizes spanning from 1,763.5 MBH up to 6,060.9 MBH. You can elect to have your boiler as:

- A combo gas-light oil burner (BGL system)

- A complete boiler-burner unit equipped with a light oil burner (BL system)

- A power burner for gas (BG system)

- Only a boiler (H system) for approved heavy-oil burners

In addition to offering flexibility when it comes to fuel, the Weil-McLain 94 Series boasts multiple installation options. You can opt to have your system in individual sections or with sections assembled at the factory. You can also choose to have a completely packaged boiler that has been assembled and fire-tested at the factory.

And if you don’t know which option is best for your facility, the experts at ATI of New York can help. We are the authorized manufacturer’s representatives for Weil-McLain and offer their entire line of cutting-edge products, including the 94 Series boiler. Let’s take a closer look at a few key features of the Weil-McLain 94 Series boiler.

Forced Draft Firing

Because it’s pressurized for forced-draft firing, the 94 Series doesn’t need a chimney. Instead, this boiler operates with nothing more than a three foot vent situated on top of the roof.This forced-draft boiler:

- Does not require any additional mechanical draft equipment

- Is more efficient due to it being pressurized

- Has reduced boiler room space requirements

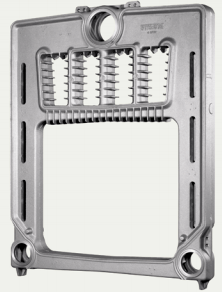

Hydro Wall Design

The 94 Series Boiler’s Hydro Wall design has an innovative water-backed combustion area with water circulating around the firebox. The sidewalls and crownsheet help create a maximized surface for heat transfer.The Hydro Wall Design also:

- Minimizes heat loss through the bottom of the boiler

- Allows it to have a lower height

- Permits installation on any floor

With cast iron parts of the boiler not facing the ground, the tougher outer skin is left to protect against corrosion and rust.

No Refractory Combustion Chamber

Because the boiler’s combustion area is surrounded by water, the burners for flame retention do not need hot refractory for combustion. This enhanced feature of the 94 helps keep boiler costs low by saving on the combustion chamber materials and the labor required to install it. In addition, there are no future replacement costs.

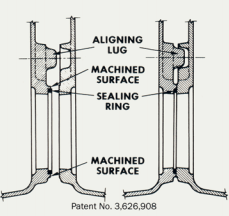

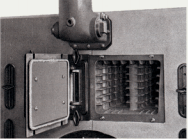

Section Sealing Method

Every port opening on the 94 boiler features a flexible elastomer sealing ring to help ensure a water-tight, permanent seal between the different sections. This unique sealing method is enhanced by the use of short draw rods to connect sections and help facilitate faster assembly of sections.As demonstrated in the illustration, the machined surface of the port opening manages the compression ratio of the sealing ring to create a critical water tight seal. The aligning lugs help ensure the sections are properly aligned during assembly. These lugs also permit positive locking of the sections.

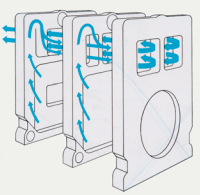

Flue Gas Traveler

Combined with an ultra-efficient three-pass design, the Weil-McLain 94 Series boiler has multiple uptakes working to:

- Force hot gasses to ensure balanced flue gas travel

- Wipe the entire flue area

- Prevent shortcuts to the chimney

By having higher velocities and a longer flue gas travel, the 94 Series boiler increases the absorption of heat of the alternate heating surfaces.

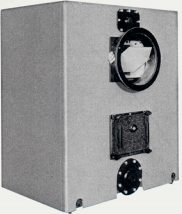

Front Cleanout Opening

To simplify and streamline maintenance and cleanings, the No. 94 boiler boasts two large cleanout doors. These openings offer complete access to the center flueways for unencumbered cleanings. The frameless doors are hinged to a center plate, sealed with a rope and then confirmed to be air tight by the use of wing nuts. As an added measure, the six cleanout plates located on the front of the boiler are rope-sealed and offer quick access for easy maintenance.

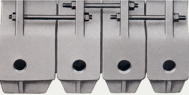

Manufactured with Short Draw Rods for Faster & Easier Assembly

No Return Header — Flanged Flue Collar

The Series 94 boiler helps save on material costs and installation time by reducing the need for a separate return header. Condensate or return water enters through the center opening and is then channeled to the right or left port openings by interior vanes in the section.

Supply Outlets for Simplified Piping

By requiring only two or one tow supply outlets, the Series 94 reduces installation time. You’ll receive three types of supply outlets as standard equipment based on your boiler size:

- 10-inch flanged top supply outlet

- Supply elbow with an 8-inch flanged opening

- Supply elbow with a 6-inch tapped opening

The outlets do feature an integrated trap that separates the water from the air.

Integrate Multiple Tankless Water Heaters

The Series 94 boiler can accommodate the installation of up to 8 tankless water heaters. When you choose to use multiple tankless water heaters, you’ll enjoy:

- The ability to access hot water at different temperatures

- The ability to have an increased volume of hot water

- The ability to access a single heater for melting snow

Contact ATI of New York for the Weil-McLain 94 Series Boiler

The Weil-McLain 94 Series boiler is nothing short of a modern marvel. And you can learn more about this cutting-edge boiler at ATI of New York. Our experienced, factory-trained sales engineers will get to know your facility’s needs and demands to ensure the 94 is the best potential solution.

Contact the experienced sales engineers of ATI of New York today.