The Prescription for the Best Pharmaceutical Industry Boiler

Pharmaceutical industry boilers are a critical component of any processing plant. Whether the steam boiler is used in the process of medicinal drying, sterilizing, and purifying; boilers used in the pharma industry must be extremely precise, which means it has high-temperature control demands.

Most pharmaceutical firms choose high-pressure steam boilers due to the simplicity and efficiency of the system. At the same time, high-pressure steam boilers can be used for direct heating as well as indirect heating. All of these reasons are why high-pressure steam boilers are the premier solution for pharmaceutical process heating.

Applied Technologies of New York offers a full suite of world-class, high-pressure and efficient boiler solutions for pharmaceutical processing firms. These pharmaceutical boilers are versatile enough to meet the vast range of needs demonstrated by the pharmaceutical industry. Continue reading for to learn more about the key considerations for choosing the best pharmaceutical industry boilers.

Boilers Used in Pharma Industry Must Produce Clean Steam

Pharmaceutical companies need the boiler to generate steam for the working process. However, not all steam is created equally. Steam quality can be categorized by its purity level, which is mandated by the end-use application. Make sure the boiler you choose can provide the quality of steam needed for your pharmaceutical facility applications.

Plant Steam

Plant steam or house steam is the lowest grade of steam. It’s used by laundries, healthcare facilities, paper & pulp, food & beverage, and petrochemicals. As the most economical type of steam to produce, plant steam can be produced by natural gas and electricity. Softened feed water can be used to reduce mineral deposits and decrease hard water.

Clean Steam

Clean steam is a step above plant steam and is used by pharmaceutical industry, laboratories, health care facilities, as well as the food & beverage industry. Clean steam contains no dissolved materials and is commonly created from reverse osmosis or deionized treatment systems. This type of steam is required in facilities producing sterile products — but where endotoxins are not a concern.

Pure Steam

Pure steam is the highest quality of steam. This type of steam is critical to biotechnology and pharmaceuticals, especially for injectable drug production. Pure steam is regularly used when absolute sterility is necessary to guarantee process repeatability.

The Fulton VSRT Leads the Pack with Clean Steam

If you’re looking for the premier boiler for producing clean steam for pharmaceutical processing facilities, the Fulton Vertical Spiral Rib Tubeless steam boiler is in a class of its own. The VSRT is the first refractory-free, fully-wetted vertical tubeless boiler.

This modern marvel represents the newly defined standard for industrial steam boiler design. The Fulton VSRT can produce steam at more than 99.75% steam quality, which is more than sufficient for most pharmaceutical processing plant’s clean steam needs.

Why Are Fulton Boilers Used in the Pharma Industry ?

For more than 50 years, Fulton has been providing boilers and innovative solutions to the healthcare industry. Fulton understands your needs for clean steam as well as reliability. Fulton Boilers are designed to meet and exceed these expectations.

Exceptional Versatility

Fulton’s boilers are versatile enough to produce clean steam for sterilization applications as well as autoclaves with a full backup of redundancy. In addition, Fulton’s boilers are suitable for traditional processes, such as central boiler plants.

Excellent Construction

These boilers are manufactured with superior construction — boasting 28% thicker construction materials compared to other boilers. This allows Fulton boilers to be more resistant to corrosion and more durable. As a result, you can spend less money and time on maintenance, chemical treatments, and equipment replacements.

Compact & Efficient

Fulton’s equipment achieves unmatched turndowns and industry leasing efficiencies. You can easily manage and monitor demand loads with smart boiler sequencing to bolster the performance of your pharmaceutical processing plant. Most importantly, these boilers can occupy less than half of the space of comparable equipment by using a modular approach.

Single-Source Solutions

Fulton’s skidded boiler systems for pharmaceutical plants are pre-piped, engineered systems, which can be customized to satisfy even the most complex operation and design requirements.

Built to Last

As a testament to Fulton’s reliable construction, every Fulton boiler is warrantied for an impressive five years. Whenever the boiler is a part of a custom engineered system, the warranty doubles to a staggering 10 years, which is simply unmatched in the industry.

Cutting-Edge Advancements

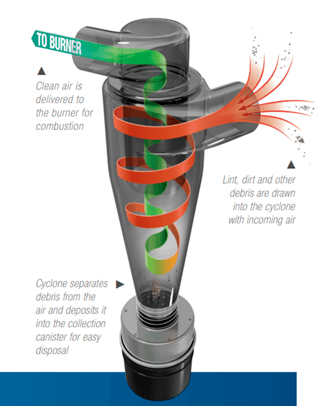

The Fulton VSRT features a patent-pending cyclonic air filter that effectively keeps the combustion chamber clear of potentially damaging particles. This innovative cyclonic filter will not clog over time and completely eliminates the need for replacement filters.

Contact ATI of New York for the Best Pharmaceutical Industry Boilers

Whether you’re considering a Fulton boiler or any other type of equipment, the experts at Applied Technologies of New York can help. As your local pharmaceutical boiler experts, we bring decades of experience helping pharmaceutical processing plants choose the best boiler for their steam, processing, and heating needs.

Contact ATI of New York today to learn more about some of the best options for your facility.